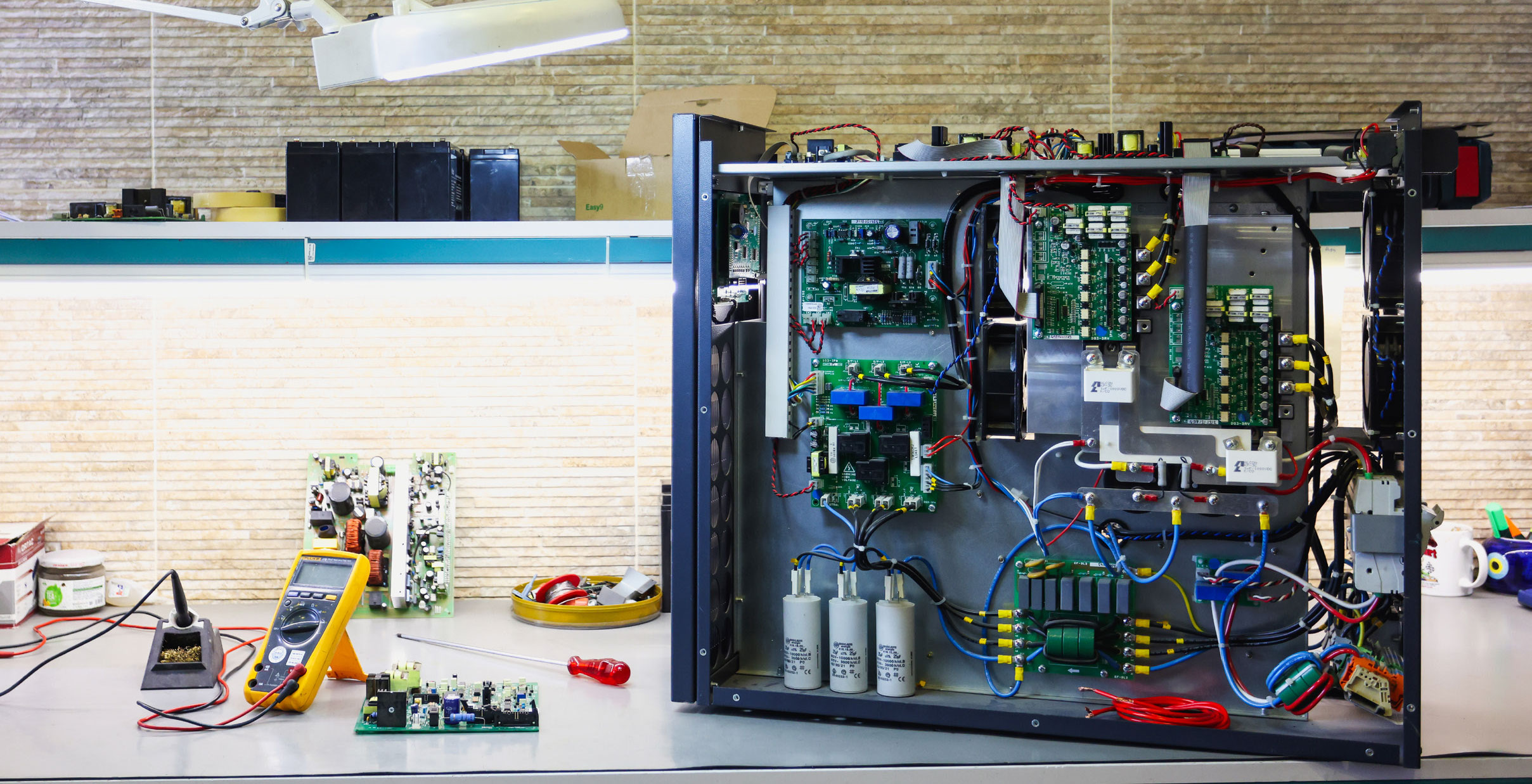

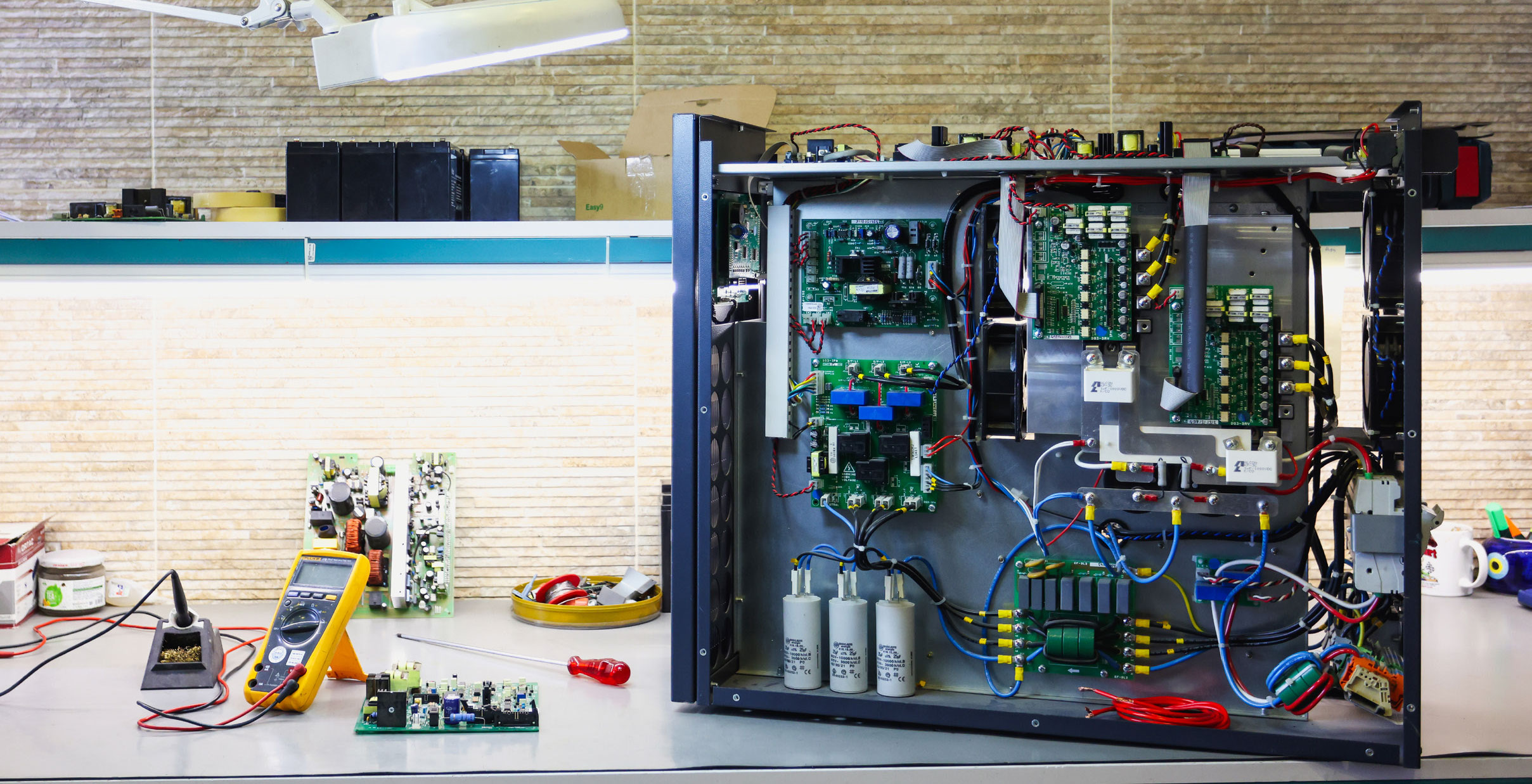

This page covers the importance of life-cycle components that degrade over time in UPS (Uninterruptible Power Supply) systems, replacement intervals and maintenance recommendations, along with a sample annual maintenance schedule.

Lifetime components are critical components that lose their performance over time and must be replaced at certain intervals. Failure to replace these materials at regular intervals can seriously affect the reliability and performance of the UPS.

Below are the most common lifespan components in UPS systems and their replacement intervals along with their descriptions.

1. Batteries

Life: Typically 3–5 years (for VRLA lead-acid batteries), up to 7–10 years for some industrial batteries.

Why Change?

- Capacity loss occurs over time.

- Internal resistance increases, which causes the battery to become insufficient during sudden loads.

- Overheating, swelling and fluid loss may occur.

Maintenance Note: Should be tested at least annually, more frequently from the 3rd year onwards.

2. DC Capacitors (Intermediate Circuit Capacitors)

Life: 5–7 years (varies depending on quality, temperature and intensity of use)

Why Change?

- Their capacities decrease over time, which negatively affects voltage regulation.

- There may be a risk of swelling, leakage or explosion.

Maintenance Note: After the 5th year, capacity measurements should be made and replaced when the values fall below the limit.

3. AC Input / Output Capacitors

Life: 5–7 years

Why Change?

- Affects power factor, causes inefficient operation.

- May adversely affect harmonics between network and UPS.

Maintenance Note: Temperature control should be done with a thermal camera and the values should be monitored.

4. Fans (Cooling Systems)

Life: 3–5 years (for continuously operating fans)

Why Change?

- Performance decreases due to wear, bearing failure or dust.

- Inadequate cooling causes UPS overheating and component failures.

Maintenance Note: Annual cleaning should be done, and noisy or irregularly operating fans should be replaced immediately.

5. Fuses / Circuit Breakers

Life: Depends on the fault condition; requires periodic inspection even if its lifespan has not expired.

Why Change?

- It may fail after overload.

- Over time, there may be oxidation on the contact surfaces.

Maintenance Note: It should be tested at least once a year and overheating should be checked with a thermal camera.

6. Relays and Contactors

Life: 5–10 years (depending on work frequency)

Why Change?

- Mechanical parts wear out over time.

- Contacts may wear out, contact errors may occur due to sparking.

- Contactor magnetic coil may fail. (Contactor strength/conductivity control)

Maintenance Note: Number of operating cycles / duration (Cycle Time) should be monitored, contacts & contactors should be checked regularly.

7. Air/Fan Filters (IP54)

Life: 6 months – 1 year (depending on the dust level of the environment)

Why Change?

- Clogged filters block air flow, reducing cooling efficiency.

Maintenance Note: It is recommended to check every 3 months and change/clean at least once a year.

8. LCD / Display Panels and Buttons

Life: 5–10 years

Why Change?

- Image loss and keystroke problems may occur.

Maintenance Note: Visual control should be performed and response time and clarity should be monitored.

General Recommendations for Lifetime Parts Replacement in UPS Systems:

- System outages can be prevented by making Planned Changes in Redundant Systems.

- Maintenance and test records should be kept regularly.

- Temperature analysis should be done at least once a year with a thermal camera.

- It should be done by authorized service teams.

Maintenance/Replacement Schedule:

You can see a sample maintenance and lifespan part replacement schedule for a medium-sized online UPS system (e.g. 10-40 kVA).

This schedule is prepared according to general usage conditions; in dustier, hotter or more humid environments, the periods may be even shorter. You can think of this plan as an annual cycle.

UPS Maintenance and Lifetime Parts Replacement Schedule (Annual Plan)

Monthly Maintenance

- UPS screen, alarm, LED and control panels are checked for operation.

- Input/output voltages and frequency are measured.

- Battery temperature and voltages are observed (if remote monitoring is available, it is also monitored from the software).

- Working environment (temperature, humidity, cleanliness) is checked.

Quarterly Maintenance

- If there are Air/Fan (IP54) filters, they are checked, cleaned or replaced if necessary.

- It is checked whether the fans are working loudly.

- General external cleaning is done for dust accumulation.

Six Month Maintenance

- All connection screws and terminals are checked for tightness.

- Battery cells are measured separately (voltage, internal resistance).

- Temperature control with thermal camera (fan, connectors, cable heads).

- Alarms and events from the UPS software are examined.

Annual Heavy Maintenance (Every Year)

- The interior of the UPS is cleaned of dust and dirt (with compressed air if necessary).

- Battery capacity test is performed (Load bank, with active output load / UPS Battery Test Mode Active)

- Fans are cleaned, replaced if necessary.

- Capacitance measurements of DC capacitors (with LCR meter) are performed.

- Relays and contactors are checked visually and functionally.

- AC output filters and fuses are reviewed.

Every 3 Years

- Battery replacement should be planned (for VRLA battery).

- A replacement decision is made based on the DC capacitor test results.

- Relay/contactor life is reviewed, replacement is made if necessary.

- Software/firmware update is made (If there is a revision).

Every 5 Years

- DC capacitors should be replaced as standard (even if the measurement is good).

- Fans should definitely be replaced (bearing life is over).

- AC input/output capacitors are replaced according to the situation.

- UPS system configuration is reviewed, if there is a load increase, an upgrade/capacity increase plan is made.

Every 7–10 Years

- Full battery group replacement (if long-life industrial battery is used).

- Relays, contactors, circuit breakers are replaced.

- A major overhaul or renovation is planned for the UPS system.

Extra Recommendations:

- Maintenance reports and test results should be archived regularly.

- If there is a monitoring system, remote monitoring should be active.

- All heavy maintenance and part replacements should be done by authorized technical personnel.

- If the UPS is operating in parallel, load sharing should also be tested at every maintenance.